In this case study, I'll break down exactly how nClarity's BuildingInsights (™), powered by the nClarity Predictive Maintenance Platform, saved a large Manufacturing client upwards of $40,000 in annual energy costs in the first year. The savings easily paid for the next 3 years of Full Service PM from our contracting partner.

One of our key contracting partners has a full service PM Manufacturing client that was looking for more uptime assurance. Being a European headquartered company, the client was also looking to achieve corporate carbon emission reduction targets.The facility runs two shifts and is cooled and ventilated by approximately twenty 30-ton packaged units varying in age and condition. Controls are in place but with limited analytics.

The client had concerns about how well the Packaged Units and systems were being managed. They weren’t particularly concerned about finding energy savings as much as they were interested in finding low cost ways to cut carbon emissions and get a better sense of security that systems would not fail.

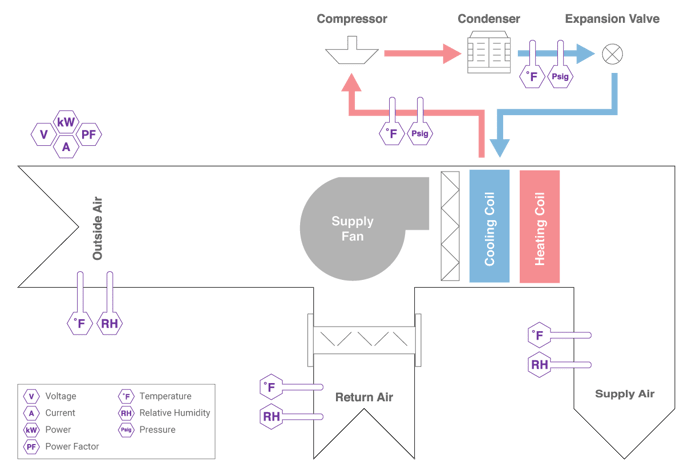

Working with nClarity, the mechanical service contractor and energy consultant configured the platform to provide 7X24 hour continuous monitoring of the facility’s packaged units. An integrated circuit board (Pulse) was installed and sensors connected to each package unit. Sensors measure high and low side pressures, pressure temperatures, Supply and Return airs and power consumption. The Pulse communicates its sensor data to an on premise, private cellular gateway that uploads data to the nClarity cloud (Microsoft Azure).

An nClarity Pulse Unit Installed On A Packaged Unit

Once installed on a packaged unit, the nClarity Pulse collects data from various systems within the unit. (See legend)

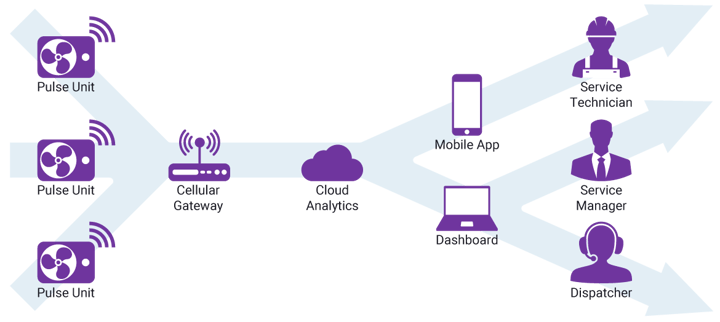

nClarity’s team has spent years building HVAC analytics and has used that expertise to optimize its analytics for use by Service Operations teams. These analytics are converted into tech-friendly BuildingInsights (™) and distributed to office staff dashboards and technician mobile devices.

The Flow of Data From the nClarity Pulse Unit

Pulse data sent through the cloud is available wherever needed, whether it be in the office or on the roof.

In this particular case, nClarity’s BuildingInsights highlighted that system fans were in operation when not needed, creating tremendous waste.

The control system was unaware. Shifting into action, the staff met with their client and educated them on their findings. They were authorized to work with their controls provider to address the issue. After being assured the requisite changes had been made, the Service Ops team checked nClarity’s dashboard only to discover the problem continued.

Again, the controls service provider was dispatched and this time the change took hold.

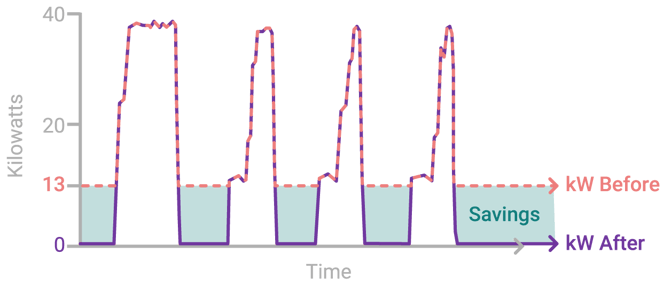

System Fan kW Usage Before & After Fan Adjustment

The BuildingInsights data fed from the nClarity Pulse revealed that the system fan was running unnecessarily when it should have been off, drawing 13kW.

The fan adjustment resulted in a 13 kW reduction per RTU. Factoring in all the RTUs, savings are projected to be $35,000-$40,000 and will supply a significant ROI on their PM services.

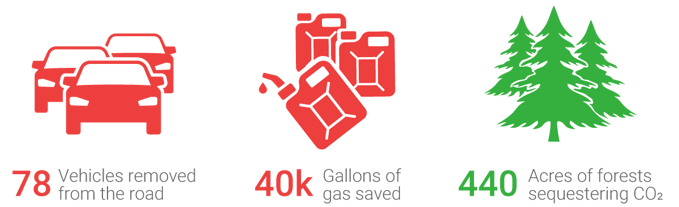

Using nClarity’s platform, the client was able to realize his carbon emission reduction target in the first 60 days of 2022.

Yearly Carbon Emission Reductions Equivalent To:

While this is just an example of some low hanging fruit that we typically find in commercial and manufacturing sites, perhaps the richer story is the failures that are prevented through Virtual Services that identify future and immediate sources of component and system failures.

Whether it’s a yellow alert indicating a downstream problem that can be dealt with at a future date or a red alert indicating imminent failure, the peace of mind gained from a Predictive Maintenance model is invaluable to facilities leaders in manufacturing environments and any other mission critical environments.

Interested in learning more about how nClarity can help your business? Fill out the form below and one of our product experts will reach out to you.